Ordina dal

Enel guida la transizione energetica con impegni concreti per l'energia pulita, investendo in rinnovabili e progetti sostenibili per un futuro migliore.

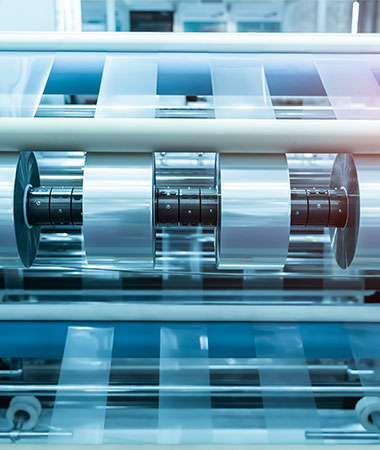

Un accordo importante per l'industria della plastica che punta su efficienza e stabilità elettrica.

L’offerta di Enel X per il mondo business, dai programmi di Demand Response al Peak Management.

L’accordo con Enel X prevede un piano triennale verso la carbon neutrality per l’azienda leader nel settore dei rivestimenti.

L’accordo con Enel X prevede un piano triennale verso la carbon neutrality per l’azienda leader nel settore dei rivestimenti.

Una partnership per maggiore sostenibilità ed efficienza energetica nel settore agro-alimentare.